Sustainable in-situ soil remediation technology

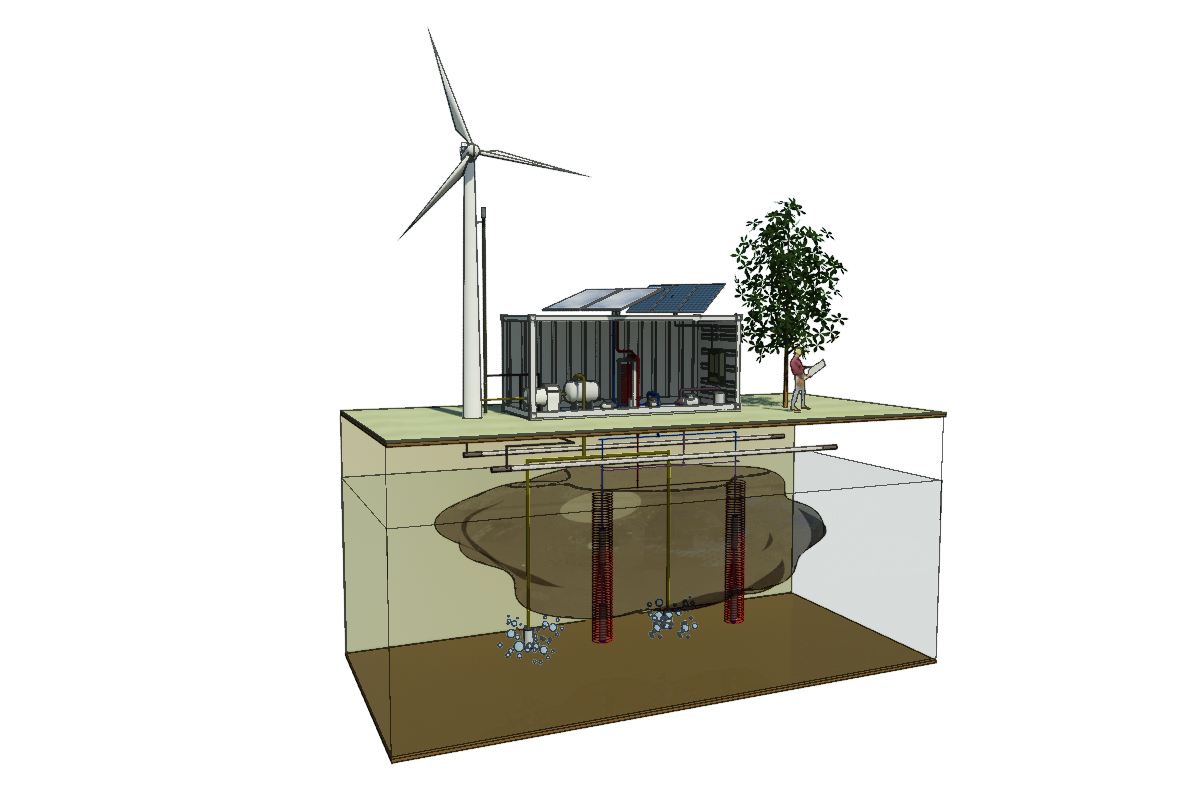

Sustainable In-Situ Soil Remediation (SISSR) technology avoids the high cost and risk associated with chemical and thermal remediation treatments by exploiting what is naturally present in the subsurface in order to immobilize and cleanup contamination. It accomplishes this by increasing temperatures and injecting air into the soil to accelerate biostimulation. An energy storage facility is not required because temporary interruptions (wind deficiencies and/or solar restrictions) allow for preferential pathways in the subsurface to be redistributed with new bacteria, making it easier for bacteria to consume the contaminants once the system starts up again. This remediation approach is classified as net zero since all energy consumed comes from renewable energy sources.

Case study

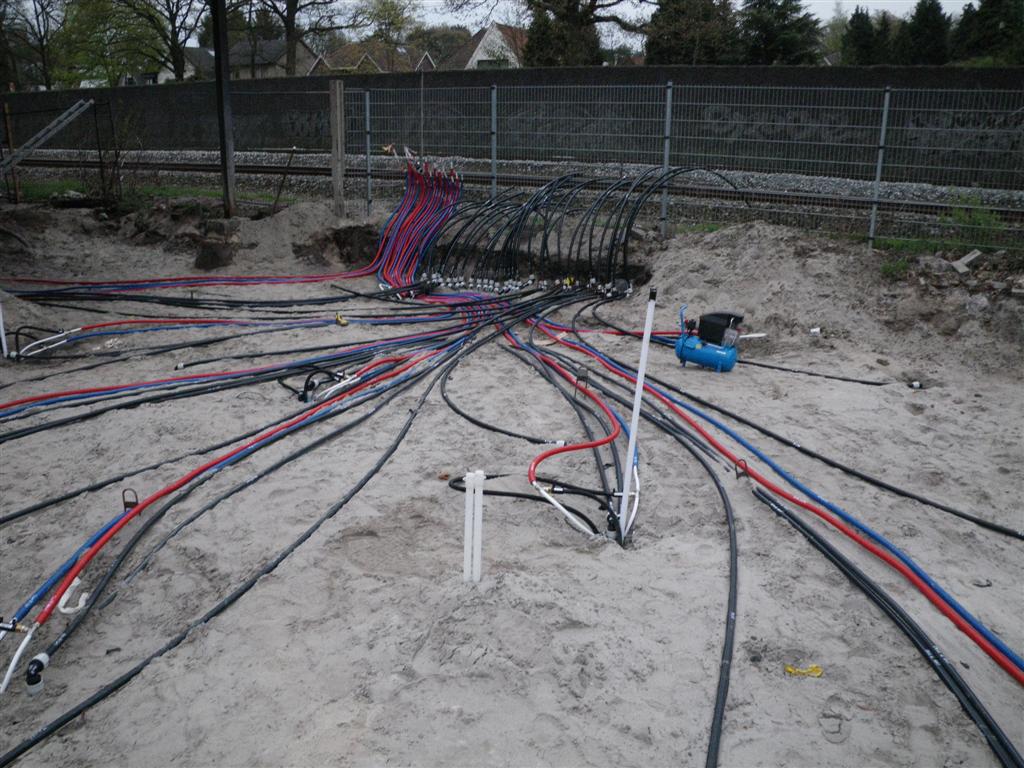

Located in Bilthoven Netherland, this site has had a long history of industrial uses dating back to 1863 when the Dutch railway company purchased it. Over the years various operations have taken place and have included: warehousing, wood, petroleum and coal distribution centers, paint company and rail yard. Since 2008, this site has sat vacant. Soil and groundwater at the site is contaminated with mineral oils starting from half a meter down to nine meters below ground surface (bgs). In 2011, contaminants located in the vadose zone (0.5 meters to 2 meters bgs) were excavated and removed. The remaining contaminants located in the saturated zone (2 to 9 meters bgs) are currently being treated with SISSR technology.